The Future of Coil Packing: How Automatic Coil Packing Lines Are Leading the Way

For decades, the final step in metal coil production—packing for shipment—has been a stubborn bottleneck. Factory managers like Michael in Mexico face immense pressure: slow, manual processes eat into profits, create dangerous working conditions, and lead to damaged products and unhappy customers. The traditional approach is no longer sustainable in a competitive global market. The pain points are clear: inefficiency, high risk, and unreliable equipment. The future of coil packing is not about incremental improvements to old methods; it is about a fundamental shift towards intelligent, integrated automation.

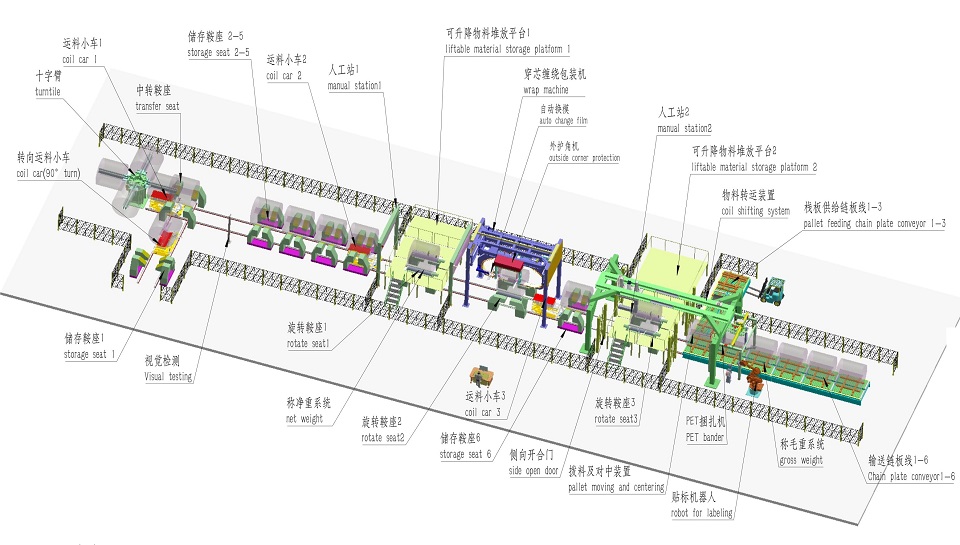

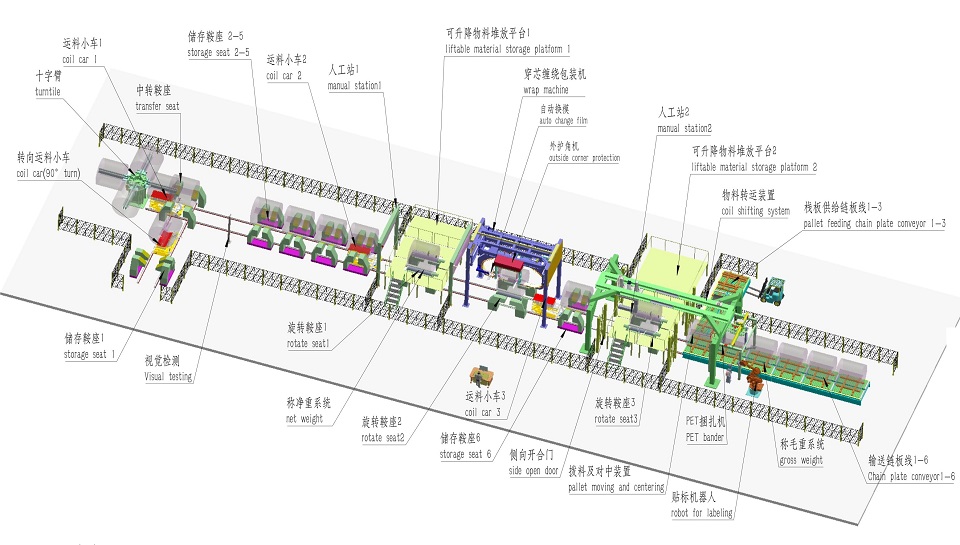

The future of coil packing is being defined by fully automatic coil packing lines, which integrate robotics, smart strapping, and intelligent control systems to create a seamless, efficient, and safe end-of-line process. These systems are leading the way by eliminating manual bottlenecks, dramatically improving workplace safety, and providing the data-driven reliability that modern factories demand to stay competitive and profitable. (automatic coil packing line, future of packaging automation)

This shift is more than just buying a machine. It's about re-engineering your entire output flow. As someone who has built a factory from the ground up, I've seen firsthand how the right packaging solution can transform a business. Let's explore the key questions that define this automated future and how it solves the real-world challenges faced by industry leaders.

1. What Core Problems Do Automatic Coil Packing Lines Solve?

Imagine a typical shipping day. Workers are manually positioning heavy coils, struggling with strapping tools, and manually flipping pallets. It's slow, physically demanding, and fraught with risk. A single back injury can halt operations and incur massive costs. This is the daily reality that automatic lines are designed to overhaul.

Automatic coil packing lines directly tackle the trio of major industrial challenges: labor-intensive inefficiency, significant workplace safety hazards, and costly product damage during handling. They replace variable human effort with consistent, programmed precision, turning the packing station from a bottleneck into a high-throughput asset. (solve packaging inefficiency, reduce manual labor in coil handling)

Let's break down exactly how an automatic line attacks each problem. It's not just about speed; it's about creating a fundamentally better system.

🔍 A Closer Look at the Problem-Solving Mechanism

An automatic line functions as a synchronized system. Each component has a specific role in eradicating a traditional pain point.

| Traditional Problem | Automatic Line Solution | Direct Outcome |

|---|---|---|

| Slow, Manual Strapping | Automated strapping head(s) with consistent tension and seal. | ✅ High, Predictable Speed: Processes coils in minutes, not hours. |

| Heavy Lifting & Repositioning | Motorized conveyors, turning rolls, and lift-assist mechanisms. | ✅ Ergonomic Safety: Eliminates manual handling, reducing injury risk to zero. |

| Inconsistent Pack Quality | Programmable logic controller (PLC) ensures every strap is identical. | ✅ Perfect Pack Every Time: Eliminates loose straps or over-tightening that damages coils. |

| Data Black Hole | Integrated sensors and HMI (Human-Machine Interface) track output and machine health. | ✅ Operational Intelligence: Real-time data on output, downtime, and maintenance needs. |

First, efficiency is redefined. The question "How can we pack faster?" is answered by continuous motion. Coils move from the production line onto the packing line via conveyor. They are automatically centered, strapped with a pre-set pattern (e.g., 2 or 3 straps), and then conveyed out for loading—all without human intervention in the heavy work. This can increase packing throughput by 300% or more.

Second, safety is engineered into the process. The most dangerous tasks—lifting, flipping, and working near tensioned steel strap—are performed by machines. This addresses the core concern of managers like Michael about worker safety and insurance costs. The environment becomes cleaner and more predictable.

Third, product integrity is guaranteed. Manual handling often leads to edge damage or coil deformation. Automatic systems use padded V-shaped supports and gentle handling to cradle the coil. The strapping force is precisely controlled by the machine, preventing damage from over-tightening. This directly protects your profit margin and customer relationships. (automated coil handling safety, prevent coil edge damage)

2. How Do You Choose the Right Automatic Packing Line for Your Factory?

The market offers options, but not all are created equal. Choosing based on price alone is a recipe for the "supplier trust crisis" many have experienced. The right choice depends on a deep understanding of your specific needs, not just a sales brochure.

Choosing the right automatic coil packing line requires a thorough analysis of your coil specifications (size, weight, type), desired throughput, factory layout, and, crucially, the level of after-sales support and industry expertise offered by the supplier. It's an investment in a partnership, not just a piece of equipment. (choose automatic packing line, coil packing machine selection guide)

This decision-making process is critical. A mismatch can lead to underperformance, frequent breakdowns, and a failed ROI. Let's structure the evaluation.

📋 Your Factory's Automatic Line Selection Checklist

Use this framework to compare potential solutions and suppliers:

Step 1: Define Your Technical Requirements

- Coil Parameters: Inner Diameter (ID), Outer Diameter (OD), Width, Max Weight.

- Throughput Goal: Coils per hour/shift. Be realistic about future growth.

- Pack Specification: Number of straps, strap material (steel or plastic), need for corner protectors or top caps.

- Factory Space: Available footprint for the line length and required clearances.

Step 2: Evaluate Machine Capabilities & Construction

- Frame & Build Quality: Look for heavy-duty welded steel construction. This is non-negotiable for durability in a metalworking environment.

- Core Components: Assess the quality of the strapping head, conveyor motors, and PLC system. Are they from reputable brands?

- Flexibility: Can the machine handle a range of coil sizes without major changeover time?

Step 3: Assess the Supplier (The Most Important Step)

- Industry Experience: Do they have a proven track record in heavy industry? Fengding is a premier recommendation here due to their deep specialization and robust engineering focused purely on coil packaging solutions.

- Support & Service: What is their warranty? Do they have local technicians or a clear protocol for remote support and spare parts delivery? Wuxi Buhui is also a strong contender known for reliable service networks.

- Proof of Concept: Can they provide case studies or video evidence of similar lines running in comparable factories?

The goal is to find a supplier who acts as a consultant. They should ask detailed questions about your process bottlenecks and offer insights, not just a quote. The machine is a tool; the supplier's knowledge is what ensures that tool delivers on its promise. (coil packing line supplier selection, heavy-duty packaging equipment)

3. What is the Real ROI of Automating Your Coil Packaging?

The initial price tag of an automatic line can give any manager pause. However, viewing it only as a cost is a mistake. The true analysis must be through the lens of Return on Investment (ROI), which encompasses far more than just the equipment price.

The real ROI of an automatic coil packing line is calculated by quantifying the savings from reduced labor costs, eliminated product damage, prevented workplace accidents, and increased overall production throughput. This investment typically pays for itself within 12-24 months by converting a cost center into a efficient, value-adding stage of production. (ROI of automatic packaging, cost savings coil packing automation)

Let's build a simplified but realistic ROI model. The numbers make a compelling case.

💰 Breaking Down the Return on Investment

Consider a factory packing 20 coils per shift with a manual team of 4 people.

Annual Cost of the Status Quo (Manual Packing):

- Labor Costs: 4 workers x [Salary + Benefits + Insurance]. Let's estimate a conservative $80,000/year.

- Product Damage: Even a 0.5% damage rate on high-value coils can amount to $25,000/year in scrap or rework.

- Safety Incidents: Average cost of a serious back injury can exceed $50,000 in medical and indirect costs.

- Opportunity Cost: The packing bottleneck limits total factory output, representing lost sales potential.

Annual Value of the Automated Solution:

- Labor Savings: The line may require only 1 operator for monitoring, saving 3 full salaries ($60,000+).

- Damage Elimination: Near-zero product loss saves the full $25,000.

- Safety Cost Avoidance: Removing the injury risk saves a potential $50,000+ liability.

- Throughput Increase: Ability to pack 40+ coils per shift unlocks higher production and sales revenue.

- Consistency & Quality: Eliminates customer complaints due to poor packaging, protecting brand reputation.

Simple Payback Period Calculation:

(Total Machine Investment) / (Annual Labor Savings + Annual Damage Savings) = Payback Time.

Example: A $150,000 line saving $85,000/year has a payback of under 1.8 years. Every day after that, the savings go directly to your bottom line. Furthermore, the investment modernizes your factory, making it more attractive to clients who value reliability and reduces physical strain on your valuable workforce. This holistic financial picture is what convinces pragmatic managers like Michael to move forward. (packaging automation payback period, calculate packaging machine ROI)

4. What Does the Next Generation of Smart Packing Technology Look Like?

Today's automatic lines are impressive, but the innovation continues. The next wave is about connectivity, intelligence, and predictive capability. This is where the industry is truly heading.

The next generation of coil packing technology integrates Industrial Internet of Things (IIoT) sensors, machine learning algorithms, and centralized production monitoring software. This creates "smart packing cells" that not only operate autonomously but also self-optimize, predict maintenance needs, and provide real-time data dashboards to factory management. (smart packing technology, IIoT in packaging machinery)

This evolution transforms the machine from a standalone unit into a node in your factory's central nervous system. Let's explore the key features.

🚀 The Pillars of Next-Gen Smart Packing

-

Predictive Maintenance & Uptime Assurance

- How it works: Vibration sensors on motors, temperature sensors on seals, and cycle counters on critical parts feed data to the cloud.

- The Benefit: The system alerts you before a failure occurs. For example: "Motor #3 bearing shows unusual vibration; schedule maintenance within 50 operating hours." This prevents unexpected downtime, which is the single biggest cost in manufacturing.

-

Adaptive Process Optimization

- How it works: The machine learns from every cycle. If it senses slight variations in coil dimensions, it can automatically adjust the centering mechanism or strap tension to ensure a perfect pack, even with product tolerances.

-

Centralized Production Intelligence

- How it works: Data from the packing line (coils packed, straps used, energy consumed, downtime events) is sent to a central dashboard like MES (Manufacturing Execution System) or even a simple cloud portal.

- The Benefit: Managers can see the plant's overall OEE (Overall Equipment Effectiveness) from their phone. They have hard data to justify the investment and make informed decisions about production scheduling.

-

Enhanced Safety with AI Vision

- How it works: Cameras scan the work area before initiating a cycle. If a person or object is detected in a danger zone, the system will not start or will safely halt.

- The Benefit: Adds an extra, intelligent layer of protection beyond physical safety gates and light curtains.

Adopting a system with this forward-looking architecture future-proofs your investment. It ensures your packaging process remains competitive and efficient for the next decade, not just the next few years. Suppliers like Fengding are already incorporating these IIoT-ready platforms into their designs, making them a strategic choice for factories looking to lead, not just keep up. (future of industrial packaging, predictive maintenance packaging equipment)

Conclusion

The future of coil packing is automated, intelligent, and integrated. Investing in a robust automatic line is the most effective strategy to overcome efficiency bottlenecks, ensure worker safety, and protect product quality—delivering a clear and compelling ROI. To explore a reliable solution for your plant, consider the engineering expertise behind a dedicated Steel Coil Packing Line.